Building Autonomous Vehicles

Moving to the US

During the final year of my bachelor’s degree I joined CETAC, a student organization with two main purposes; bridging the gaps between industry and academia, as well as offering American internship opportunities to students. The former was achieved by our sales team, which I personally decided to join. We were tasked with inviting industry leaders to share their professional experiences with the university students, mainly in the form of lunch lectures. The internship opportunities were located by our dedicated job team, who negotiated the openings before distributing them though the organization.

During my time with CETAC, I received the offer to conduct an internship in the US. The opportunity was given to me by Amerden, a company on Florida’s east coast that specializes in automated vehicles for industry applications. I accepted this offer together with two friends from the organization: Gustav Karlsson and Marcus Forsberg.

Half a year later we set foot in sunny St Augustine, where we got started with our projects. My project of choice was to develop a bespoke a set of transmitting and receiving antenna pairs, designed to replace a deprecated third party component of a client’s system. The client needed to refurbish their entire fleet of vehicles - and successful delivery of this component would solidify a full refurbishing contract for the business. However, replicating the collision avoidance systems would be anything but easy. A combination of outdated components, missing documentation and a high degree of physical wear made the old PCB constituents close to uninterpretable. Moreover, the existing assemblies were all protected with a thick layer of potting. This severely restricted the access capabilities to the components themselves. For the months that followed, my work place would be overflowing with wires, oscilloscopes, microcontrollers and everything that makes electrical R&D work what we know and love.

The first objective was to gain an understanding for the existing PCB structures and functionalities. After completely depotting one antenna system, the PCBs could be analyzed in more detail. Some of the electrical components were easily recognizable. Others, such as integrated components with lacking description codes, were impossible to visually identity. To gain clarity in the functionality of these components, I instead studied the logical connections of the PCBs themselves. By means of this approach, I was able to identify amplification stages, filters and other high level functionalities of the circuit.

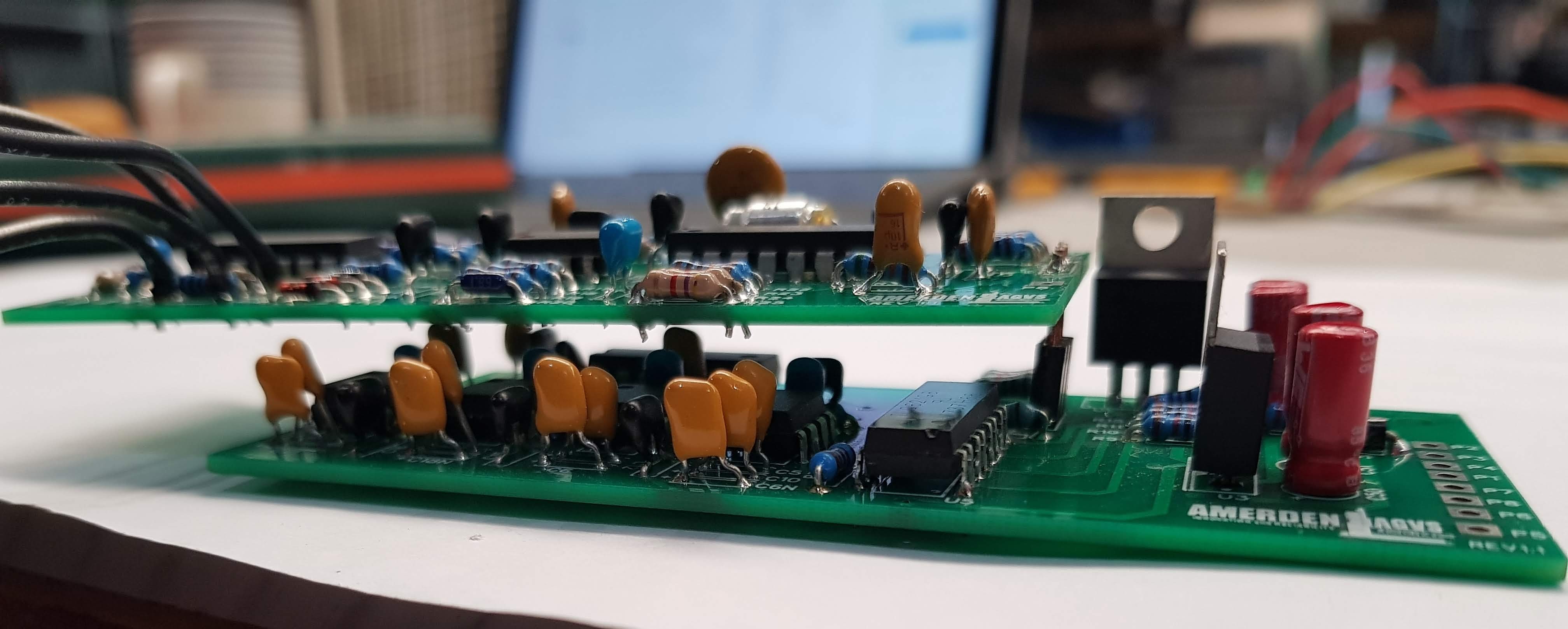

By carefully analyzing the original circuit, I successfully identified the original PCB functionalities. This meant that I was ready to start with my own construction. I designed the first iteration on simple proto-boards. This allowed for a high level of flexibility in component magnitude testing. I additionally desided to use microcontrollers in my implementation. These allowed for seamless transition between the binary vehicle logic and the desired frequency of the antenna, which I programmed using Arduino. I was then able to use the Arduino for burning bootloaders into my permanent microcontrollers. Once all of the constituents had been adequately tested, I had custom PCBs made in order to permanently house the developed architecture. Custom casings were also fabricated with the help of 3D printing technology.

By carefully analyzing the original circuit, I successfully identified the original PCB functionalities. This meant that I was ready to start with my own construction. I designed the first iteration on simple proto-boards. This allowed for a high level of flexibility in component magnitude testing. I additionally desided to use microcontrollers in my implementation. These allowed for seamless transition between the binary vehicle logic and the desired frequency of the antenna, which I programmed using Arduino. I was then able to use the Arduino for burning bootloaders into my permanent microcontrollers. Once all of the constituents had been adequately tested, I had custom PCBs made in order to permanently house the developed architecture. Custom casings were also fabricated with the help of 3D printing technology.

My client was located in San Francisco, which made the testing procedure for my component a significant challenge. I got around this problem in two ways. Firstly, I created a simulated working environment in my local office. This contraption replicated the infrastructure present at the customer site and allowed me to test the majority of product functionalities myself. Secondly, I sent prototypes with intrinsic adjustability to the client - and guided them to perform the necessary investigations. This allowed for effective testing with minimal lead time and traveling.

The project turned out to be a big success thanks to the trust and support offered by my manager, the hours of hard work and dedication, as well as the effective collaboration maintained together with my client. With a sense of immense pride and happiness, and with a million dollar contract to show for it, I considered this chapter of my life complete.

Links